PTR

Ladder type Trays

Ladder type trays (PTR) are our workhorse, which grant a high load capacity even with reduced thicknesses and result in cost reduction and easy handling during installation.

This type of cable tray is particularly suitable for medium and large sized cables, providing great capacity and the proper ventilation.

Our PTR is assembled by robotized welding with MAG process between side-rail and rung, granting high quality and reliability standards, a very important requirement in the most demanding sectors such as construction and Oil & Gas.

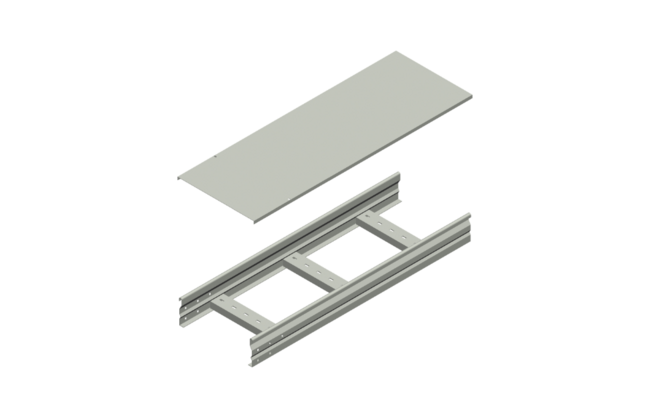

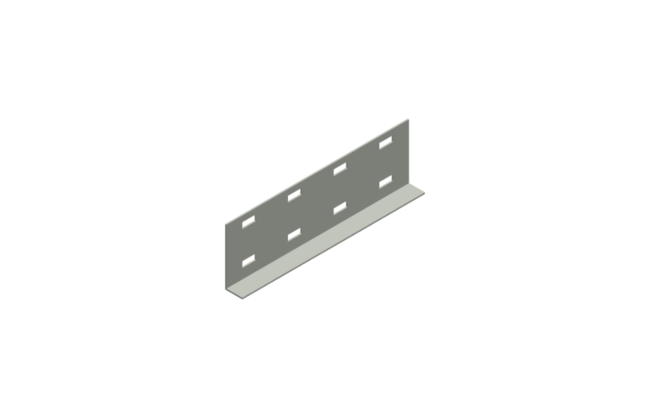

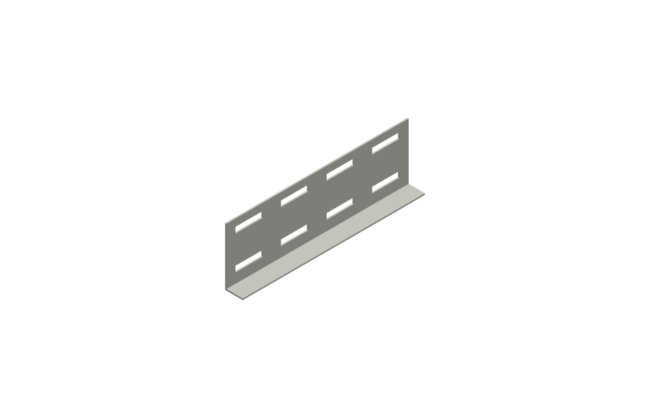

| Straight element |

| 90° horizontal bend |

| 45° horizontal bend |

| Hinged bend element |

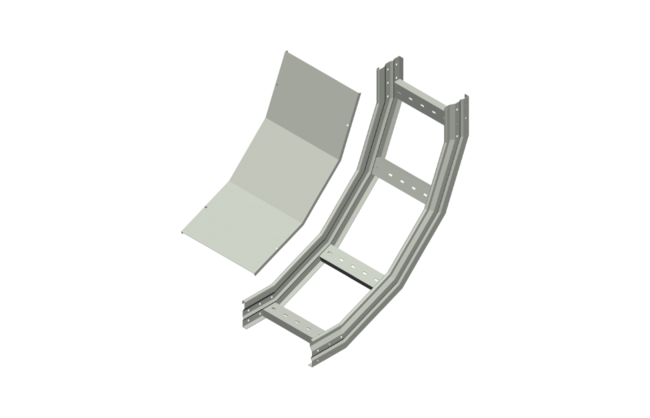

| 90° internal vertical bend |

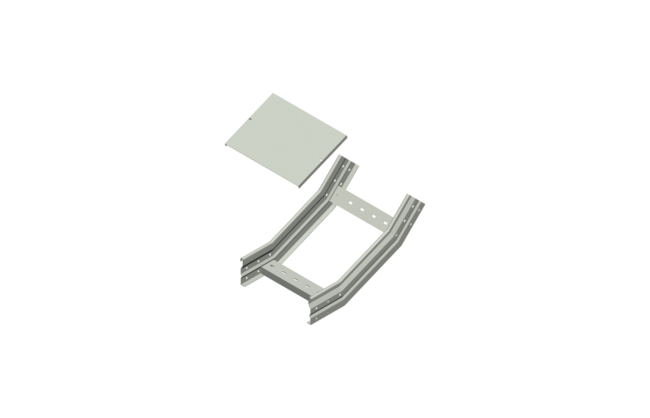

| 45° internal vertical bend |

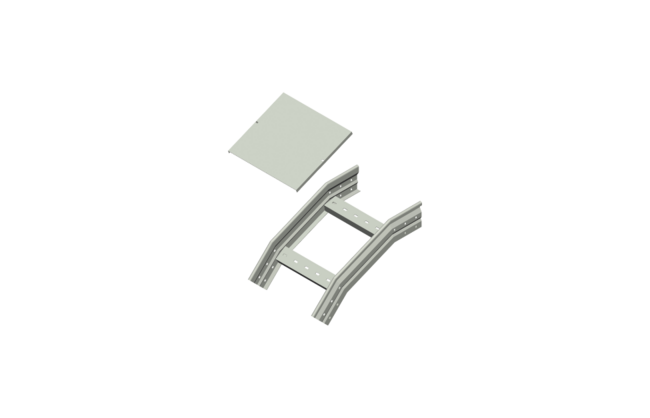

| 90° external vertical bend |

| 45° external vertical bend |

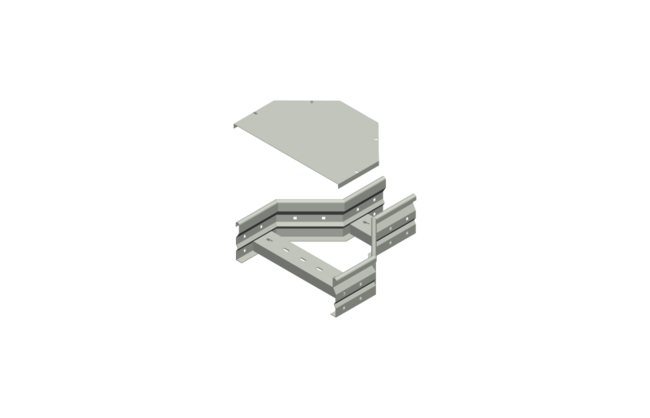

| Tee |

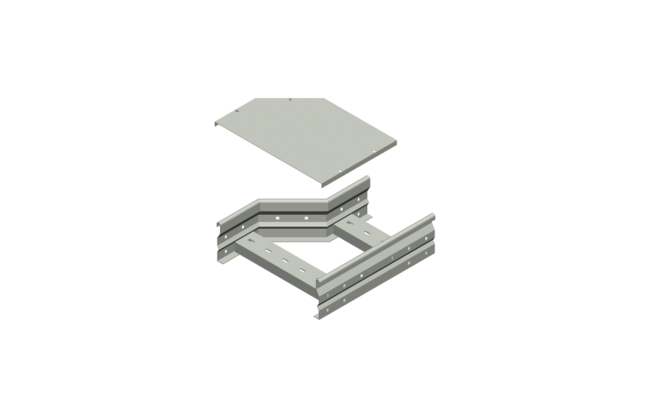

| Cross |

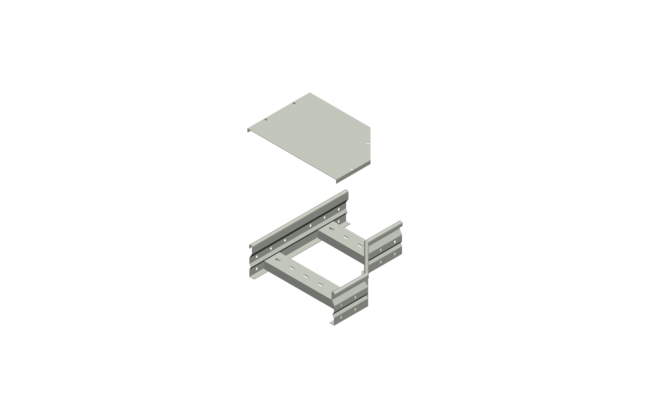

| Central reduction |

| Right reduction |

| Left reduction |

| Reduction joint |

| End plate |

| Divider |

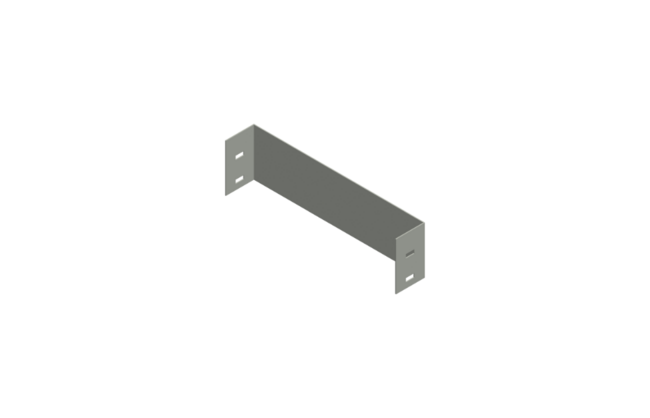

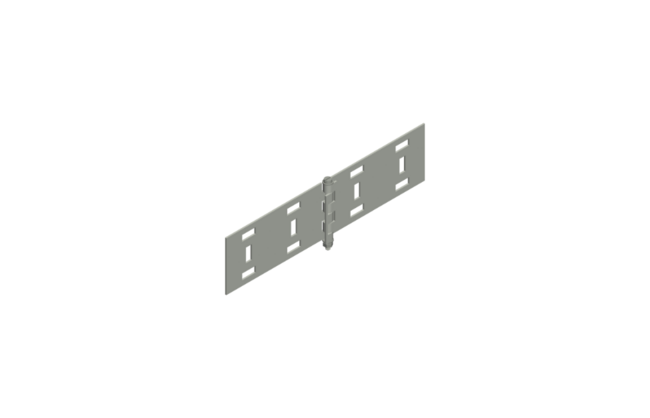

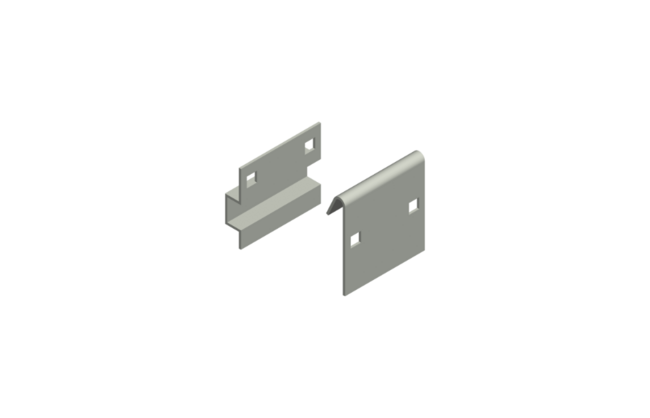

| Normal joint |

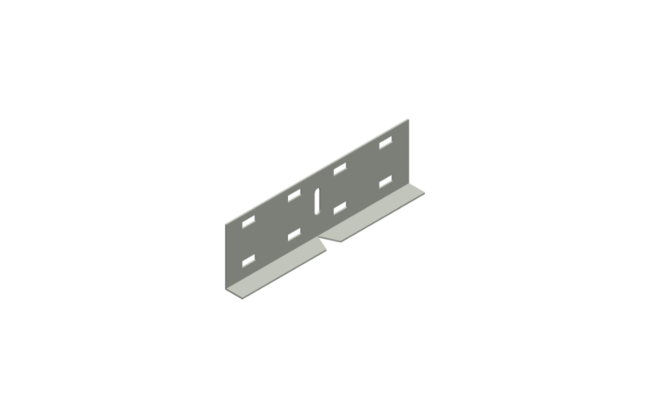

| Expansion joint |

| Adjustable horizontal joint |

| Horizontal hinged joint |

| Vertical hinged joint |

| Lateral connection joint |

| Bolt for joint |

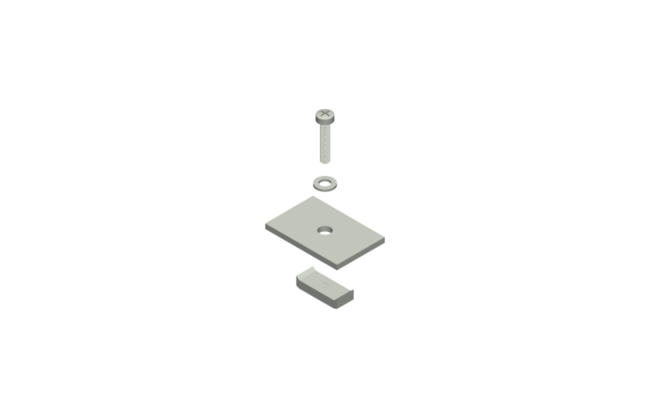

| Support fixing kit |

| Rack fixing kit |

| Cover spacer |

| Cover fixing |

| Hook type cover fixing |