Preamble

Taking knowledge from our construction and maintenance works, since 1945 we have been serving the plant industry also with our mechanical workshops doing carpentry works such as:

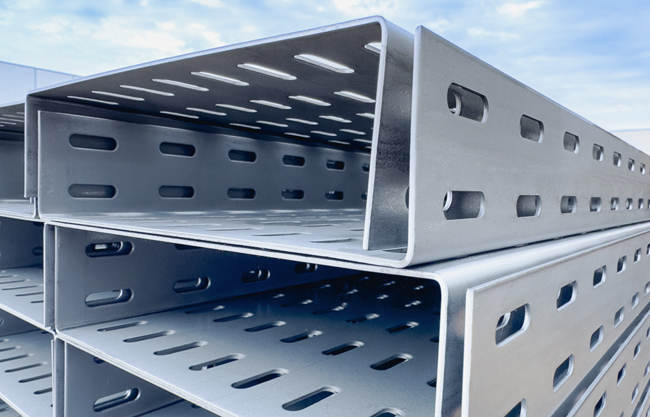

- cable trays

- supports & fasteners

- lighting fixtures poles

- switchboards frames

- instrument supports

- other metallic structures

We usually deal with Hot Dip Galvanized Steel after fabrication and Stainless Steel, on request also Sendzimir and Aluminium.

Dealing with a market that constantly plays downwards in terms of quality and solidity of materials, we are proud of having maintained over the years the robustness of our products, which comply with the most restrictive standards and specifications of the Oil & Gas sector.

Custom made

Our lean but well-organized production plant allows us to be extremely flexible and able to customize lots even of small dimensions, meeting the client’s needs where they have to comply with stringent and mandatory specifications, as required by the Oil & Gas, chemical, pharmacy and food sectors.

We are familiar with handling of specific requirements, not only during the engineering phase and the manufacturing of personalized items, in terms of material thickness and dimensions, but also during the whole supply chain including certifications, documentation and tests.

Browse Products

| PFLR |

Reinforced cable trays |

| SF |

Supports and Fasteners |

Projects

| Project |

Fano Revamping |

| Client |

Gruppo Antonini Energy S.r.l. |

| End user |

ENI / SNAM |

| Site |

Fano (PU) |

| Activity |

Cable support system production

|

| Amount |

> 620.000 € |

| Project |

Sabratha Platform |

| Client |

Gruppo Antonini S.p.A. |

| End user |

Melliath Oil & Gas BV |

| Site |

Gruppo Antonini |

| Activity |

Cable support system production

|

| Amount |

> 380.000 € |

| Project |

SIOT Terminal |

| Client |

SIOT / Fincantieri |

| End user |

SIOT |

| Site |

S.I.O.T. Via Rio Primario, 2 (TS) |

| Activity |

Cable support system production

|

| Amount |

> 155.000 € |

| Project |

Ravenna CCS |

| Client |

R.I.ECO. S.p.A. |

| End user |

ENI / SNAM |

| Site |

Eni S.p.A. Via Primo Lacchini, 99 |

| Activity |

Cable support system production

|

| Amount |

> 460.000 € |

| Project |

Panigaglia Vessel Reloading |

| Client |

Sa.Gest. S.r.l. |

| End user |

Snam Rete Gas / GNL Italia |

| Site |

GNL Italia S.p.A. |

| Activity |

Cable support system production

|

| Amount |

> 150.000€ |

| Project |

Maboqueiro Platform |

| Client |

Gruppo Antonini S.p.A. |

| End user |

Azule Energy |

| Site |

Gruppo Antonini |

| Activity |

Cable support system production

|

| Amount |

> 350.000 € |

| Project |

FSRU Piombino |

| Client |

Novello S.r.l. |

| End user |

SNAM FSRU Italia S.r.l. |

| Site |

Golar Tundra Rigassificatore |

| Activity |

Cable support system production

|

| Amount |

> 400.000 € |

| Project |

Condensation Unit Enefit Power |

| Client |

Siirtec Nigi S.p.A. |

| End user |

Enefit Power AS |

| Site |

Narva, Estonia |

| Activity |

Cable support system production

|

| Amount |

> 305.000 € |

| Project |

Argo-Cassiopea Project |

| Client |

Rema Tarlazzi S.p.A. |

| End user |

Eni S.p.A. |

| Site |

ENIMED Gela |

| Activity |

Cable support system production

|

| Amount |

> 250.000 € |

| Project |

Ettore Majorana |

| Client |

SOMI S.r.l. |

| End user |

ENEL |

| Site |

Termini Imerese, Palermo |

| Activity |

Cable support system production

|

| Amount |

> 198.000 € |

| Project |

Orion Engineered Carbons |

| Client |

SIE S.r.l. |

| End user |

Orion Engineered Carbons S.r.l. |

| Site |

Orion Engineered Carbons (Ravenna) |

| Activity |

Cable support system production

|

| Amount |

> 237.000 € |

| Project |

Tunnel Frejus |

| Client |

NIDEC ASI S.A. |

| End user |

SFTRF |

| Site |

Tunnel Frejus |

| Activity |

Cable support system production

|

| Amount |

> 255.000 € |

| Project |

Sarroch Refinery |

| Client |

SIE S.r.l. |

| End user |

Saras S.p.A. |

| Site |

Saras S.p.A. (Sarroch) |

| Activity |

Cable support system production

|

| Amount |

> 264.000 € |

| Project |

Zürich Airport |

| Client |

Moditech S.r.l. |

| End user |

Flughafen Zürich |

| Site |

Flughafen Zürich |

| Activity |

Cable support system production

|

| Amount |

> 54.000 € |

| Project |

Chemicals plants |

| Client |

Desmet Ballestra S.p.A. |

| End user |

Manufacturers of: detergents, surfactants and chemicals |

| Site |

Desmet Ballestra |

| Activity |

Cable support system production

|

| Amount |

> 370.000 € |

| Project |

Amur Gas Processing Plant |

| Client |

Tecnimont S.p.A. |

| End user |

Gazprom |

| Site |

Amur Gas Processing Plant |

| Activity |

Cable support system production

|

| Amount |

> 2.970.000 € |

| Project |

CORU (Moscow Refinery) |

| Client |

Tecnimont Russia |

| End user |

Gazprom |

| Site |

Газпромнефть – Московский НПЗ Kapotnya 2-Y Kvartal, 1, корп. 3 Moscow Russia |

| Activity |

Cable support system production

|

| Amount |

> 2.450.000 € |

| Project |

MO.S.E. |

| Client |

Ing. E. Mantovani S.p.A. |

| End user |

Consorzio Venezia Nuova |

| Site |

Venezia, Italy |

| Activity |

Cable support system production

|

| Amount |

1.100.000 € |